Recently, Hailiang Co, Ltd. (hereafter Hailiang) spearheaded the drafting of Seamless Copper Alloy Tube for Water Desalting Applications (GB/T 23609-2023) and participated in the drafting of Test Method for Erosion and Corrosion of Marine Water for Copper and Copper Alloys (GB/T 42654-2023). These standards have been approved by the State Administration for Market Regulation (Standardization Management) and are set to be implemented from March 1, 2024.

Two National Standards

These two standards outline the classification, marking, technical requirements, testing methods, inspection regulations, signs, packaging, transportation, storage, accompanying documents, and order forms of seamless copper alloy tubes for water desalting applications. They also describe the test methods for erosion and corrosion of marine water for copper and copper alloys, including the principles, test conditions, reagents, equipment, samples, and test procedures, results and reports.

The two standards provide a unified specification and guidance for the design, manufacturing, and use of seamless copper alloy tubes for water desalting applications, improving the performance and lifespan of equipment and providing scientific test methods for erosion and corrosion of marine water for copper and copper alloys.

Drafting Departments and Key Drafters of the Two Standards

The drafting of the two standards was organized by Hailiang’s Research Institute, with the active participation of Shanghai Hailiang. Hailiang has consistently focused on technological innovation and advancing the industry, and the standards will provide strong support and guidance to relevant industries, which further underscores the company’s technical capabilities and industry influence.

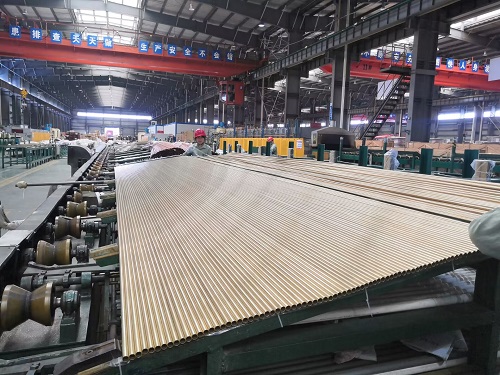

Seamless Copper Alloy Tubes of Shanghai Hailiang

Hailiang’s Research Institute was formed by the merger of the original research institute and the technical center. It is responsible for product and process research and development management, production technology improvements, production line planning, production equipment coordination, and intellectual property management within the company. Under the leadership of Dr. Peng Long (Assistant President of Hailiang Group and Hailiang Co, Ltd., and Director of the Research Institute), the institute actively conducts research at various production bases, vigorously promotes intellectual property management and the establishment of industry standards.

Research Institute’s Research at Production Bases

As the innovation engine of Hailiang, the Research Institute will continue to collaborate with various departments and production bases, uphold an innovative spirit, pursue excellence, and make even greater contributions to advancing the industry and the national progress.